Laminating Machines

The first Neschen K600 laminator was presented at Photokina in 1974. Designed by Neschen, produced in Europe, with high added value for our customers worldwide. Our laminators are not only built for our customers, but with our customers. During the development phase, we have intensively coordinated the machine design with our customers worldwide. Our aim is to build machines that function practically in their everyday work. We attach great importance to ensuring that our customers can carry out maintenance and repairs themselves.

Would you like to become a reseller of Neschen laminators? Do you need a list of our Neschen laminator sales partners worldwide? Please contact our customer service.

NESCHEN HotLam 1650 DoubleH

A new development of Neschen. The real multi-talented laminator!

Description

Product Information

The Neschen HotLam 1650 DoubleH is perfect for mounting and laminating up to 1650 mm width. Additionally offers this multi-talent laminator the possibility of high quality hot encapsulation with high working speed. Furthermore, this laminator offers a built-in vertical trimmer, to cut away overlapping excess media. The HotLam 1650 DoubleH includes heatable main rollers, fully adjustable up to 160°C for enhanced lamination of hot melt or heat-activated laminating films. Two sets of main rollers eliminate the need for a “cooling down” period between hot and cold laminating jobs. This laminator has seven material shafts. Four shafts are swing out loaded and on top with combi function. Combi shafts can unwind or either windup, as required by the operator. The HotLam 1650 DoubleH features two in feed tables with a built-in adjustable retractable trough, for the easier handling of up to 10m large size print media. The tables swings up allowing full and easy access to the rollers when webbing the machine. An additional control panel at the rear of the machine gives optimum output control and simplifies the webbing process even further.

Features

- max. 1650 mm working width

- wide range of material and high flexibility

- maximum speed of 8 m/min for increased production capacity

- electrical nip adjustment of 40 mm for precise operation

- heated main rollers (160°C) for superb lamination performance

- variable roller technology for better processing of soft substrates

- the combination shaft (bottom), for roll-to-roll operation

- flip up infeed tables to facilitate easy setup

- pull-out trough for easy feeding of single prints up to 10 m

- additional control panel at the rear of the machine

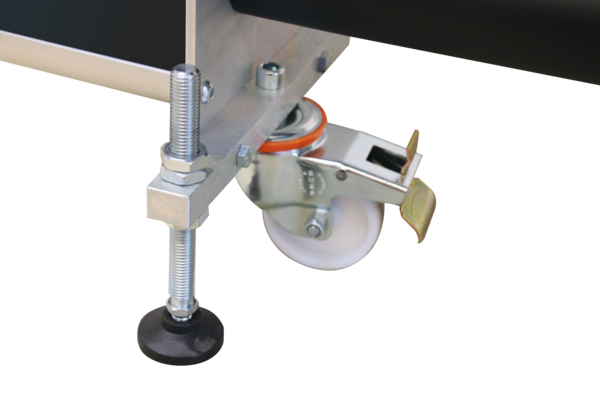

- auto grip- and swing out supply shafts for user friendly material feeding

- roll to roll built in

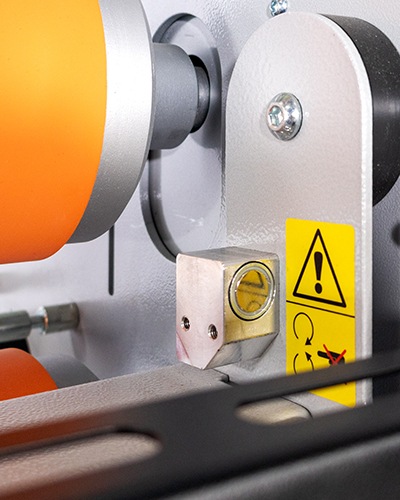

- outboard brakes for a better control of material unwind

- robust model range

Safety

- foot switch for hands free operation

- self-checking safety eyes for increased operator safety

- removable finger guard ledges

- CE certified

Downloads

| 6039986 | Neschen HotLam 1650 DoubleH | |

| 6040877 | 76 mm > 150 mm | Industrial core adapter set of 2 pcs. |

| 6045674 | Set | Infeed table add-on pack |