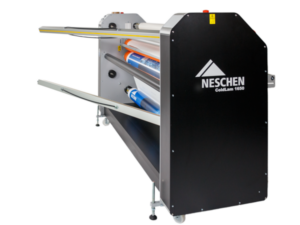

Neschen unveils the new ColdLam 1650 SW laminator – the evolution of the winning model ColdLam 1650

Neschen, a pioneer in laminator technology, sets new standards with the introduction of the new Neschen ColdLam 1650 SW. As an evolution of the proven ColdLam 1650, this innovative laminator takes handling to a new level.

The ColdLam 1650 SW combines all the advantages of the successful ColdLam 1650 and sets new benchmarks in terms of handling and user-friendliness with its two swing-out shafts. The easy and careful operation for both humans and the processed material makes the ColdLam 1650 SW an outstanding choice for diverse applications.

“The Neschen ColdLam 1650 SW is more than a laminator – it is the answer to our customers’ needs for advanced technology and superior ergonomics. Despite the slightly additional space required for the swing-out shafts, it provides an unbeatable gain in comfort and efficiency in day-to-day operations. Additionally, it helps protect the backs of our employees, contributing actively to health protection. With the introduction of the Neschen ColdLam 1650 SW, we complete our portfolio, offering a comprehensive selection of laminators that meet the highest standards and all budgets,” says Stephan Liegerer, Head of the Machine Department at Neschen.

With a width of up to 1,650 mm, the laminator is ideal for mounting and laminating prints. The top roller, continuously heated up to 70 °C, allows the processing of cold material, especially in winter, ensuring smooth production.

An outstanding quality feature of both the entire Neschen laminator range and the ColdLam 1650 SW evolution model is the integrated compressor, which operates without the need for a separate compressed air connection. The constant pressure on the rollers ensures a perfect straight run for both the medium and the laminate. With stored parameters, this function promises nearly flawless and consistently reproducible results, further contributing to the outstanding quality of lamination.

The Neschen ColdLam 1650 SW laminator maintains its versatility in processing a wide range of materials, including cardboard, photo paper, and MDF panels. The feed table with integrated unwind tray ensures easy handling of large-format media. Folding up the feed table and the rear control panel improves process control and facilitates work.

The roll-to-roll functionality allows easy winding of the material, while the continuously adjustable processing speed of up to 8 m/min offers maximum flexibility. External brakes enable the adjustment of winding tension for optimal results. Self-diagnosing light barriers and a detachable finger protection strip ensure the highest operating safety. The laminator operates with only a 230 V connection, facilitating its integration into various work environments.

Orders for the Neschen ColdLam 1650 SW are now open. For more information, visit the product site: ColdLam 1650 SW